InfinitForm Bridges the Design-to-Manufacturing Gap with AI Generative Engineering

Manufacturing-first platform unifies design and production with automated engineering intelligence, cutting design cycles by up to 80% to shorten time-to-production

LOS ANGELES, Jan. 28, 2026 (GLOBE NEWSWIRE) -- InfinitForm, an innovator in AI solutions for manufacturing engineering, today launched its Generative Engineering Platform, the next stage in the evolution of design for manufacturability in upstream physical AI. The platform marries proprietary, GPU-accelerated solvers with InfinitForm's AI Co-Pilot, enabling engineers to automate DFM analysis while optimizing for performance and cost. InfinitForm beta customers such as NASA, Yamaha Motor Company, and BMW have seen a reduction in design cycles by 60 – 80%, significantly increasing throughput and freeing teams to focus on higher-value innovation.

Closing the Gap Between Design and Manufacturing

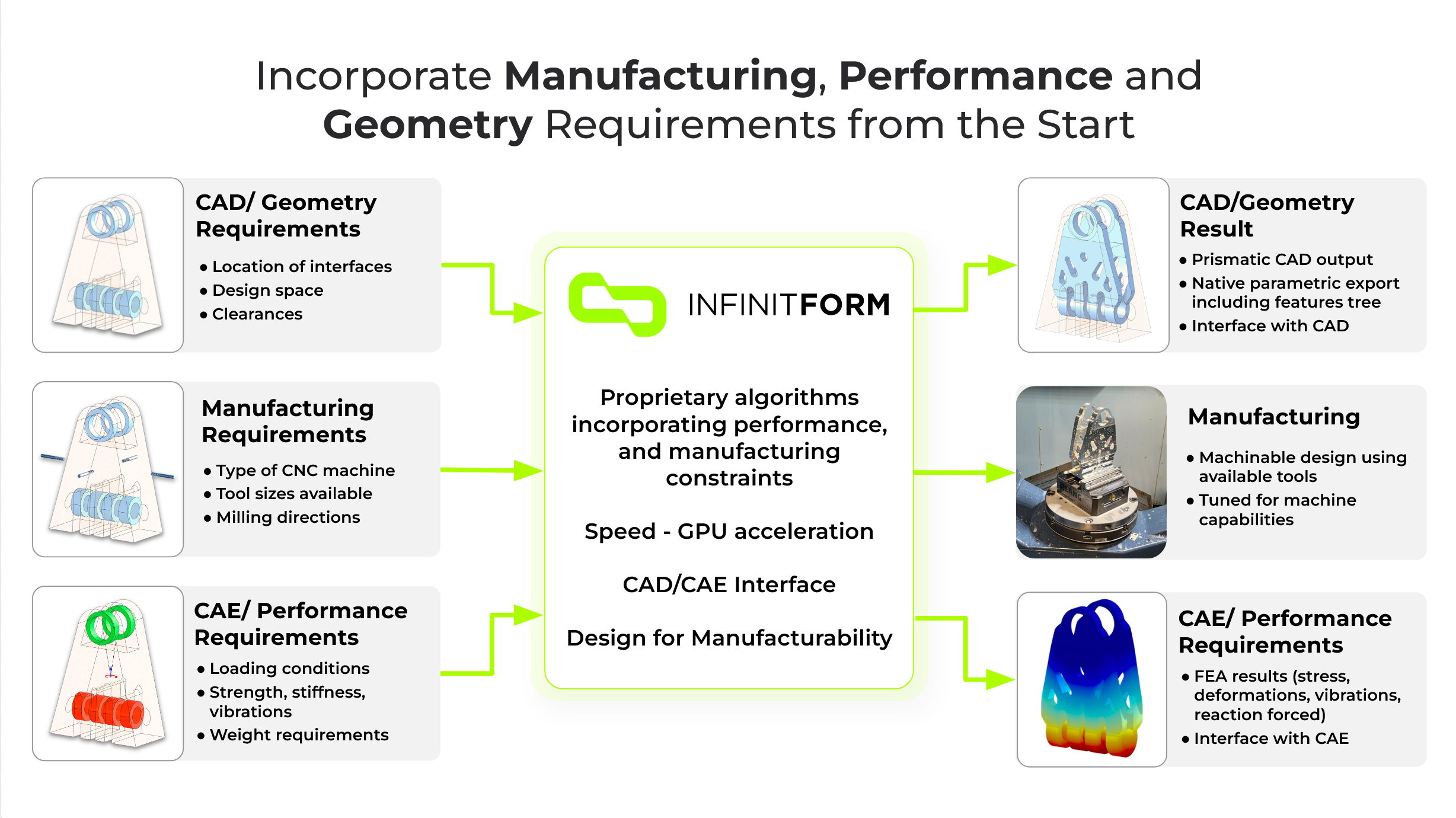

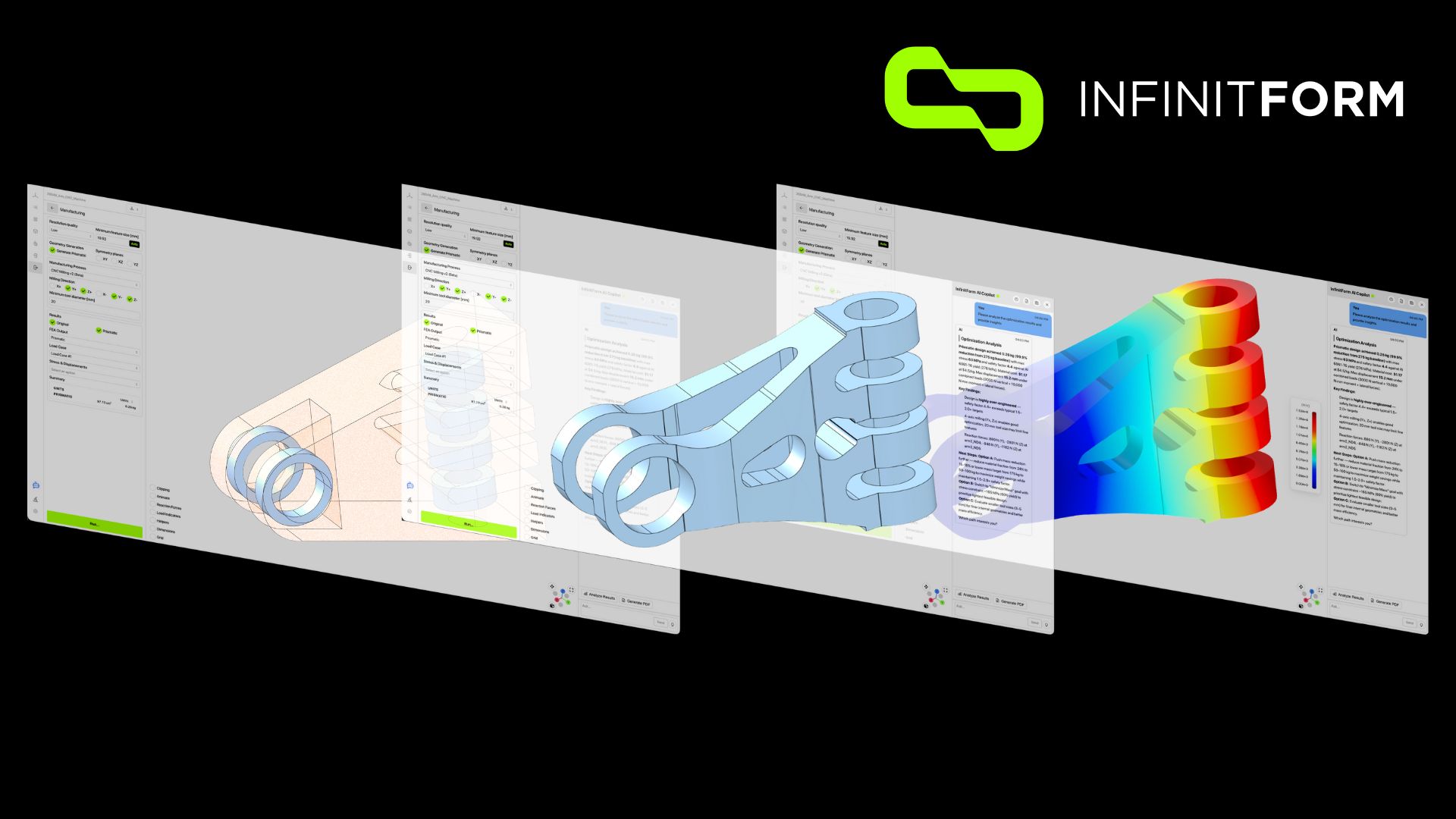

The InfinitForm Generative Engineering Platform is a software-as-a-service (SaaS) platform that integrates with computer-aided design (CAD) workflows and uses artificial intelligence (AI) to optimize design for manufacturability. The platform fosters a manufacturing-first approach that extends generative design to all traditional manufacturing methods, providing engineers and designers with automated simulation and intelligence tools to bridge the gap between design and production.

“Design and manufacturing have long operated in silos, creating inefficiencies and costly delays,” said Dr. Michael Bogomolny, Founder and CEO of InfinitForm. “While traditional generative design tools were intended to bridge this gap, they largely optimize for additive manufacturing and ignore the constraints of most production methods. With InfinitForm, we combine design optimization with manufacturing intelligence, so engineers no longer have to choose between performance and manufacturability.”

InfinitForm’s Generative Engineering Platform automates design while optimizing for manufacturing processes, including CNC machining, die casting, injection molding, extrusion, additive manufacturing, and hybrid manufacturing. Automated analysis accounts for multiple manufacturability variables, including wall thickness, draft angles, tool size and accessibility, tolerance stack-up, assembly complexity, and tooling feasibility.

Shortening Time to Production

The InfinitForm AI Co-Pilot amplifies rather than replaces engineering expertise to accelerate decision-making, freeing design engineers to focus on innovation rather than manufacturability trade-offs. The platform enables design engineers to explore more concepts with confidence that the results will be manufacturable and structurally sound.

Manufacturing handoffs are drastically accelerated from weeks to days, as AI-optimized outputs reduce revision cycles and improve first-pass manufacturing yields.

The Generative Engineering Platform also features a Privacy-First Architecture to protect intellectual property. Customer designs are never used to train platform algorithms, so proprietary data is always protected.

“Our goal is to empower engineers with AI design and engineering tools that unlock innovation and new efficiencies rather than replace their expertise,” said Bogomolny. “Our manufacturing-first platform amplifies engineering knowledge, accelerating DFM processes and allowing engineers to focus on creative design rather than creating manual iterations.”

InfinitForm generates prismatic engineering designs as part of its manufacturing-first approach. To further streamline customer workflows, the company has partnered with Autodesk Fusion and Siemens NX and is a Research Associate with Dassault Systèmes SOLIDWORKS, providing parametric designs with full design history natively within those CAD systems.

InfinitForm will be exhibiting at SOLIDWORKS’ 3DEXPERIENCE World event in partnership with NVIDIA and HP, on February 1 in Houston. For more information, visit www.3dexperienceworld.com.

InfinitForm is also offering a free 30-day trial of its Generative Engineering Platform. To learn more, visit https://cabinet.infinitform.com/register.

About InfinitForm

InfinitForm is an engineering software company founded by experts in simulation, computational geometry, high-performance computing (HPC), and software architecture. InfinitForm acts as physical AI infrastructure, bringing physics-based reasoning and manufacturability into early-stage product design. The company’s SaaS tools unify design optimization and Design for Manufacturability (DFM) into a single, intelligent workflow. InfinitForm helps design, mechanical, and industrial engineers reduce iteration cycles, improve manufacturability, and unlock new levels of innovation – delivering higher-performance products faster.

For more information, visit www.infinitform.com.

Contact:

David Parmet

Firecracker PR for InfinitForm

818-317-4687

David@firecrackerpr.com

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/3b827d8b-e4ca-45ac-894b-6240dd61a5c8

https://www.globenewswire.com/NewsRoom/AttachmentNg/df07f223-de70-462d-a62d-34bd71b71611

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.